2000 Series Aluminum Alloy Pipe

Custom Solution

Guoxin manufactures 1000 series to 7000 series aluminum alloy products such as pipes, rods and profiles since 2006, please tell us your needs like aluminum alloy grade, specifications and heat treatment of this 2000 series aluminum alloy, our company can provide aluminum alloy process solution according to the customer demands.

For more information about aluminum and aluminum alloy grade used in different countries, please click here for reference: Aluminum Grade

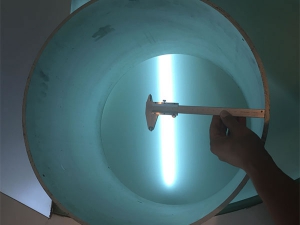

Our Aluminum Extrusion Press, for making Seamless Pipes with diameters as follows:

| Equipment |

Products |

Outer diameter |

Inner diameter |

| 100MN double action direct extrusion press |

seamless aluminum alloy pipe |

225-507mm |

195-435mm |

| 55MN double action indirect extrusion press |

seamless aluminum alloy pipe |

70-265mm |

50-254mm |

| 28MN double action indirect extrusion press |

seamless aluminum alloy pipe |

70-137mm |

35-125 |

| 1880UST double action direct extrusion press |

seamless aluminum alloy pipe |

28-88mm |

14-78mm |

| 1100UST double action direct extrusion press |

seamless aluminum alloy pipe |

25-64mm |

3-55mm |

Here are Recommend Aluminum Alloy Products

2024 Aluminum Alloy Pipe

2024 Aluminum Alloy is applied for making aircraft frame, rivet, missile components, truck wheel hub, propeller components, aircraft skin, construction and transport structures, and other structural parts.

| Alloy |

Major alloying element (mass fraction) (%) |

| Si |

Fe |

Cu |

Mn |

Mg |

Cr |

Zn |

Ti |

Al |

| 2024 Aluminum Alloy |

0.5 |

0.5 |

3.8~4.9 |

0.3~0.9 |

1.2~1.8 |

0.1 |

0.25 |

0.15 |

the rest part |

| Aluminum Alloy |

Mechanical and physical properties |

| tensile strength (25°C) (MPa) |

yield strength (25°c) (MPa) |

hardness 500kg 10mm |

elongation 1.6mm(1/16in) thickness |

max shear stress (MPa) |

| 2024-T351 |

470 |

325 |

120 |

10 |

285 |

| weldability |

machinability |

corrosion resistance |

electricity conductivity 20℃(68℉)

(%IACS) |

density

(20℃) (g/cm3) |

| limited |

great |

poor |

30~40 |

2.78 |

The Recommend Products also as follows:

| Aluminum Alloy Products |

Applications |

|

| 2014 Aluminum Alloy Pipe |

2014 aluminum alloy can be applied for occasions with requirements of high strength, high hardness and high temperature. It can be used as aircraft materials, forgings, thick metal plates and extruded materials, wheels and structural parts, spacecraft parts, the first fuel tank of multistage rocket, truck frame, suspension parts. |

Inquiry |

| 2219 Aluminum Alloy Pipe |

2219 aluminum alloy can be applied for oxidizer tank in space racket, supersonic aircraft skin and structural components. The operating temperature of 2219 aluminum alloy is about -270~300℃,it has good welding performance and high fracture toughness. During T8 state, the aluminum alloy has good resistance to stress corrosion cracking. |

Inquiry |

| 2618 Aluminum Alloy Pipe |

2618 aluminum alloy can be used for making die forgings and impact forgings, as well as piston and aircraft engine parts. |

Inquiry |

| 2A50 Aluminum Alloy Pipe |

2A50 aluminum alloy is used for making complex shaped medium strength spare parts. |

Inquiry |

| 2A70F Aluminum Alloy Pipe |

2A70F aluminum alloy is used for making aircraft skin, aircraft engine, pistons, guide wheels, roulette. |

Inquiry |

Guoxin can offer 2000 Series Aluminum Alloy Pipes as follows:

2024 Aluminum Alloy Pipe

| Alloy |

Major alloying element (mass fraction) (%) |

| Si |

Fe |

Cu |

Mn |

Mg |

Cr |

Zn |

Ti |

Al |

| 2024 Aluminum Alloy |

0.5 |

0.5 |

3.8~4.9 |

0.3~0.9 |

1.2~1.8 |

0.1 |

0.25 |

0.15 |

the rest part |

2014 Aluminum Alloy Pipe

| Alloy |

Major alloying element (mass fraction) (%) |

| Si |

Fe |

Cu |

Mn |

Mg |

Cr |

Zn |

Ti |

Al |

| 2014 Aluminum Alloy |

0.5~1.2 |

0.7 |

3.9~5.0 |

0.4~1.2 |

0.2~0.8 |

0.1 |

0.25 |

0.15 |

the rest part |

2219 Aluminum Alloy Pipe

| Alloy |

Major alloying element (mass fraction) (%) |

| Si |

Fe |

Cu |

Mn |

Mg |

Cr |

Zn |

Ti |

Al |

| 2219 Aluminum Alloy |

0.2 |

0.3 |

5.8~6.8 |

0.2~0.4 |

0.2 |

--- |

0.1 |

0.1~0.25 |

the rest part |

2618 Aluminum Alloy Pipe

| Alloy |

Major alloying element (mass fraction) (%) |

| Si |

Fe |

Cu |

Mn |

Mg |

Cr |

Zn |

Ti |

Al |

| 2618 Aluminum Alloy |

0.1~0.25 |

0.9~1.3 |

1.9~2.7 |

--- |

1.3~1.8 |

--- |

0.1 |

0.04~0.1 |

the rest part |

2A50 Aluminum Alloy Pipe

| Alloy |

Major alloying element (mass fraction) (%) |

| Si |

Fe |

Cu |

Mn |

Mg |

Cr |

Zn |

Ti |

Al |

| 2A50 Aluminum Alloy |

0.7~1.2 |

0.7 |

1.8~2.6 |

0.4~0.8 |

0.4~0.8 |

--- |

0.3 |

0.15 |

the rest part |

2A70 Aluminum Alloy Pipe

| Alloy |

Major alloying element (mass fraction) (%) |

| Si |

Fe |

Cu |

Mn |

Mg |

Cr |

Zn |

Ti |

Al |

| 2A70 Aluminum Alloy |

0.35 |

0.9~1.5 |

1.9~2.5 |

0.2 |

1.4~1.8 |

--- |

0.3 |

0.02~0.1 |

the rest part |

2011 Aluminum Alloy Pipe

| Alloy |

Major alloying element (mass fraction) (%) |

| Si |

Fe |

Cu |

Mn |

Mg |

Cr |

Zn |

Ti |

Al |

| 2011 Aluminum Alloy |

0.4 |

0.7 |

5.0~6.0 |

--- |

--- |

--- |

0.3 |

--- |

the rest part |

2017 Aluminum Alloy Pipe

| Alloy |

Major alloying element (mass fraction) (%) |

| Si |

Fe |

Cu |

Mn |

Mg |

Cr |

Zn |

Ti |

Al |

| 2017 Aluminum Alloy |

0.2~0.8 |

0.7 |

3.5~4.5 |

0.4~0.1 |

0.4~0.8 |

0.1 |

0.25 |

0.15 |

the rest part |

2036 Aluminum Alloy Pipe

| Alloy |

Major alloying element (mass fraction) (%) |

| Si |

Fe |

Cu |

Mn |

Mg |

Cr |

Zn |

Ti |

Al |

| 2036 Aluminum Alloy |

0.5 |

0.5 |

2.2~3.0 |

0.1~0.4 |

0.3~0.6 |

0.1 |

0.25 |

0.15 |

the rest part |

2124 Aluminum Alloy Pipe

| Alloy |

Major alloying element (mass fraction) (%) |

| Si |

Fe |

Cu |

Mn |

Mg |

Cr |

Zn |

Ti |

Al |

| 2124 Aluminum Alloy |

0.2 |

0.3 |

3.8~4.9 |

0.3~0.9 |

1.2~1.8 |

0.1 |

0.25 |

0.15 |

the rest part |

2218 Aluminum Alloy Pipe

| Alloy |

Major alloying element (mass fraction) (%) |

| Si |

Fe |

Cu |

Mn |

Mg |

Cr |

Zn |

Ti |

Al |

| 2218 Aluminum Alloy |

0.9 |

1 |

3.5~4.5 |

0.2 |

1.2~1.8 |

0.1 |

0.25 |

--- |

the rest part |

2319 Aluminum Alloy Pipe

| Alloy |

Major alloying element (mass fraction) (%) |

| Si |

Fe |

Cu |

Mn |

Mg |

Cr |

Zn |

Ti |

Al |

| 2319 Aluminum Alloy |

0.2 |

0.3 |

5.8~6.8 |

0.2~0.4 |

0.02 |

--- |

0.1 |

0.1~0.2 |

the rest part |

2A01 Aluminum Alloy Pipe

| Alloy |

Major alloying element (mass fraction) (%) |

| Si |

Fe |

Cu |

Mn |

Mg |

Cr |

Zn |

Ti |

Al |

| 2A01 Aluminum Alloy |

0.5 |

0.5 |

2.2~3.0 |

0.2 |

0.2~0.5 |

--- |

0.1 |

0.15 |

the rest part |

2A02 Aluminum Alloy Pipe

| Alloy |

Major alloying element (mass fraction) (%) |

| Si |

Fe |

Cu |

Mn |

Mg |

Cr |

Zn |

Ti |

Al |

| 2A02 Aluminum Alloy |

0.3 |

0.3 |

2.3~3.2 |

0.45~0.7 |

2~2.4 |

--- |

0.1 |

0.15 |

the rest part |

2A06 Aluminum Alloy Pipe

| Alloy |

Major alloying element (mass fraction) (%) |

| Si |

Fe |

Cu |

Mn |

Mg |

Cr |

Zn |

Ti |

Al |

| 2A06 Aluminum Alloy |

0.5 |

0.5 |

3.8~4.3 |

0.5~1.0 |

1.7~2.3 |

--- |

0.1 |

0.03~0.15 |

the rest part |

2A10 Aluminum Alloy Pipe

| Alloy |

Major alloying element (mass fraction) (%) |

| Si |

Fe |

Cu |

Mn |

Mg |

Cr |

Zn |

Ti |

Al |

| 2A10 Aluminum Alloy |

0.25 |

0.2 |

3.9~4.5 |

0.3~0.5 |

0.15~0.3 |

--- |

0.1 |

0.15 |

the rest part |

2A11 Aluminum Alloy Pipe

| Alloy |

Major alloying element (mass fraction) (%) |

| Si |

Fe |

Cu |

Mn |

Mg |

Cr |

Zn |

Ti |

Al |

| 2A11 Aluminum Alloy |

0.7 |

0.7 |

3.8~4.8 |

0.4~0.8 |

0.4~0.8 |

--- |

0.3 |

0.15 |

the rest part |

2A14 Aluminum Alloy Pipe

| Alloy |

Major alloying element (mass fraction) (%) |

| Si |

Fe |

Cu |

Mn |

Mg |

Cr |

Zn |

Ti |

Al |

| 2A14 Aluminum Alloy |

0.6~1.2 |

0.7 |

3.9~4.8 |

0.4~1.0 |

0.4~0.8 |

--- |

0.3 |

0.15 |

the rest part |

2A16 Aluminum Alloy Pipe

| Alloy |

Major alloying element (mass fraction) (%) |

| Si |

Fe |

Cu |

Mn |

Mg |

Cr |

Zn |

Ti |

Al |

| 2A16 Aluminum Alloy |

0.3 |

0.3 |

6.0~7.0 |

0.4~0.8 |

0.05 |

--- |

0.1 |

0.1~0.2 |

the rest part |

2A17 Aluminum Alloy Pipe

| Alloy |

Major alloying element (mass fraction) (%) |

| Si |

Fe |

Cu |

Mn |

Mg |

Cr |

Zn |

Ti |

Al |

| 2A17 Aluminum Alloy |

0.3 |

0.3 |

6.0~7.0 |

0.4~0.8 |

0.25~0.45 |

--- |

0.1 |

0.1~0.2 |

the rest part |

2A80 Aluminum Alloy Pipe

| Alloy |

Major alloying element (mass fraction) (%) |

| Si |

Fe |

Cu |

Mn |

Mg |

Cr |

Zn |

Ti |

Al |

| 2A80 Aluminum Alloy |

0.5~1.2 |

1.0~1.6 |

1.9~2.5 |

0.2 |

1.4~1.8 |

--- |

0.3 |

0.15 |

the rest part |

2A90 Aluminum Alloy Pipe

| Alloy |

Major alloying element (mass fraction) (%) |

| Si |

Fe |

Cu |

Mn |

Mg |

Cr |

Zn |

Ti |

Al |

| 2A90 Aluminum Alloy |

0.5~1.0 |

0.5~1.0 |

3.5~4.5 |

0.2 |

0.4~0.8 |

--- |

0.3 |

0.15 |

the rest part |