- Home

- Products

- Aluminum Alloy

- 4000 Series Aluminum Alloy

4000 Series Aluminum Alloy

Aluminum-silicon alloy has characteristics of heat resistance and wear resistance. This 4000 series aluminum alloy contains silicon content of about 4.5-6.0%. Typical 4000 series aluminum alloy rod is made of 4A01 aluminum alloy. Generally, the 4000 series aluminum alloy can be used as construction materials, machine parts, forging and welding materials, featuring with low melting point and high corrosion resistance.

Our company provides

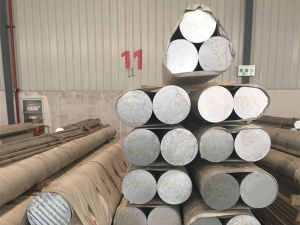

The 4000 series aluminum alloy products of our company mainly include aluminum alloy pipes, aluminum alloy rods and bars, aluminum alloy profiles.

| Aluminum Alloy Grade | Applications | |

| 4032 Aluminum Alloy | 4032 aluminum alloy is used for making piston and heat-resistant parts | Inquiry |

| 4A11 Aluminum Alloy | 4A11 aluminum alloy can be applied for making piston and heat-resistant parts | Inquiry |

| 4A13 Aluminum Alloy | 4A13 aluminum alloy is used for making plate or ribbon shape brazing material, radiator brazing sheet, as well as foil brazing layer | Inquiry |

| 4A17 Aluminum Alloy | 4A17 aluminum alloy is applied for making plate brazing material, ribbon brazing material, radiator brazing sheet, and aluminum foil brazing layer | Inquiry |

| 4043 Aluminum Alloy | 4043 aluminum alloy is used as aluminum alloy welding filler metal, including welding strip, welding rod, welding wire, etc. | Inquiry |

| 4004 Aluminum Alloy | 4004 aluminum alloy is used for making brazing sheet, radiator brazing sheet, as well as aluminum foil brazing layer. | Inquiry |

| Alloy | Major alloying element (mass fraction) (%) | ||||||||||

| Si | Fe | Cu | Mn | Mg | Cr | Zn | Ti | Others | Al | ||

| single | total | ||||||||||

| 4032 Aluminum Alloy | 11.0~13.5 | 1.0 | 0.5~1.3 | --- | 0.8~1.3 | 0.1 | 0.25 | --- | 0.05 | 0.15 | The rest part |

| 4A11 Aluminum Alloy | 11.5~13.5 | 1.0 | 0.5~1.3 | 0.2 | 0.8~1.3 | 0.1 | 0.25 | 0.15 | 0.05 | 0.15 | The rest part |

| 4A13 Aluminum Alloy | 6.8~8.2 | 0.5 | 0.15 | 0.5 | 0.05 | --- | --- | 0.15 | 0.05 | 0.15 | The rest part |

Inquiry Form