- Home

- Products

- Aluminum Alloy

- 2000 Series Aluminum Alloy

2000 Series Aluminum Alloy

Aluminum-copper alloy has easy cut performance, it can be hardened after heat treatment. 2000 Series aluminum alloy is a typical hard aluminum alloy made of Al-Cu-Mg alloy. The 2000 series aluminum alloy can be widely applied for aircraft frame, rivets, truck wheels, propeller components, and other structural parts. It is a kind of lightweight high strength aluminum alloy material used as cutting materials, forging materials, conductive materials, decorative materials, and aircraft materials.

Our company provides

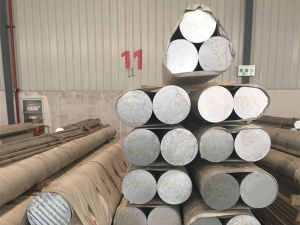

The 2000 series aluminum alloy products of our company mainly include aluminum alloy pipes, aluminum alloy rods, aluminum alloy plates and aluminum alloy profiles.

| Aluminum Alloy Grade | Applications | |

| 2014 Aluminum Alloy | 2014 aluminum alloy can be applied for occasions with requirements of high strength, high hardness and high temperature. It can be used as aircraft materials, forgings, thick metal plates and extruded materials, wheels and structural parts, spacecraft parts, the first fuel tank of multistage rocket, truck frame, suspension parts. | Inquiry |

| 2219 Aluminum Alloy | 2219 aluminum alloy can be applied for oxidizer tank in space racket, supersonic aircraft skin and structural components. The operating temperature of 2219 aluminum alloy is about -270~300℃,it has good welding performance and high fracture toughness. During T8 state, the aluminum alloy has good resistance to stress corrosion cracking. | Inquiry |

| 2618 Aluminum Alloy | 2618 aluminum alloy can be used for making die forgings and impact forgings, as well as piston and aircraft engine parts. | Inquiry |

| 2A50 Aluminum Alloy | 2A50 aluminum alloy is used for making complex shaped medium strength spare parts. | Inquiry |

| 2A70 Aluminum Alloy | 2A70 aluminum alloy is used in aircraft skin, pistons of aircraft engine, guide wheels, roulette, etc. | Inquiry |

| 2011 Aluminum Alloy | 2011 aluminum alloy can be used for making screws, and machining parts with good cutting performance. | Inquiry |

| 2017 Aluminum Alloy | 2017 aluminum alloy is the first used 2000 series aluminum alloy for industrial applications, mainly applied in making rivets, universal mechanical components, structural parts, conveyor components, propellers and accessories. 2036 aluminum alloy is used as automotive body sheet. | Inquiry |

| 2124 Aluminum Alloy | 2124 aluminum alloy is applied as aircraft and spacecraft structural parts. | Inquiry |

| 2218 Aluminum Alloy | 2218 aluminum alloy can be used in aircraft engine and diesel engine pistons, aircraft engine cylinder head, jet engine impeller and compressor ring. | Inquiry |

| 2319 Aluminum Alloy | 2319 aluminum alloy can be used as welding electrode and soldering material for 2219 aluminum alloy. | Inquiry |

| 2A01 Aluminum Alloy | 2A01 aluminum alloy is used for making structural rivets with operating temperature no more than 100℃. | Inquiry |

| 2A02 Aluminum Alloy | 2A02 aluminum alloy can be applied as axial compressor blades of turbojet engine with operating temperature of 200~300℃. | Inquiry |

| 2A06 Aluminum Alloy | 2A06 aluminum alloy can be used for aircraft frame with operating temperature of 150~250℃, as well as spacecraft structural rivets with operating temperature of 125~250℃. | Inquiry |

| 2A10 Aluminum Alloy | 2A10 aluminum alloy has higher strength than 2A01 aluminum alloy, it is used for making spacecraft structural rivets with operating temperature no more than 100℃. | Inquiry |

| 2A11 Aluminum Alloy | 2A11 aluminum alloy is applied for making medium-strength aircraft structural components, medium-strength aircraft bolts and rivets, propeller blades, transportation tools and construction structural parts. | Inquiry |

| 2A14 Aluminum Alloy | 2A14 aluminum alloy is applied for making custom shaped forgings and die forgings. | Inquiry |

| 2A16 Aluminum Alloy | 2A16 aluminum alloy can be applied for making aircraft components and spacecraft components with operating temperature of 250~300℃. It is also for welding container and airtight passenger cabin working under room temperature or high temperature. | Inquiry |

| 2A17 Aluminum Alloy | 2A17 aluminum alloy is applied for making spacecraft spare parts with operating temperature of 225~250℃. | Inquiry |

| 2A80 Aluminum Alloy | 2A80 aluminum alloy can be used for making aircraft engine blades, compressor blades, impeller, pistons, and other spare parts in high operating temperature. | Inquiry |

| 2A90 Aluminum Alloy | 2A90 aluminum alloy is applied for making aircraft engine piston. | Inquiry |

Features of 2000 series Aluminum Alloy

1. 2xxx series aluminum alloy has high strength and heat resistant performance, can be used as components under work temperature of 150°C. While the temperature exceeds 125°C, 2000 series aluminum alloy has higher strength even than 7075 aluminum alloy.

2. This aluminum alloy has good molding performance during annealing or quenching, it can be well hardened after heat treatment with specific heat treating process.

3. This 2000 series aluminum alloy is not good in corrosion resistance, covering the aluminum alloy by using pure aluminum can solve the problem, and make the aluminum alloy well protected.

6. During welding, it may cause cracks, which can be avoided with riveting or special welding techniques.